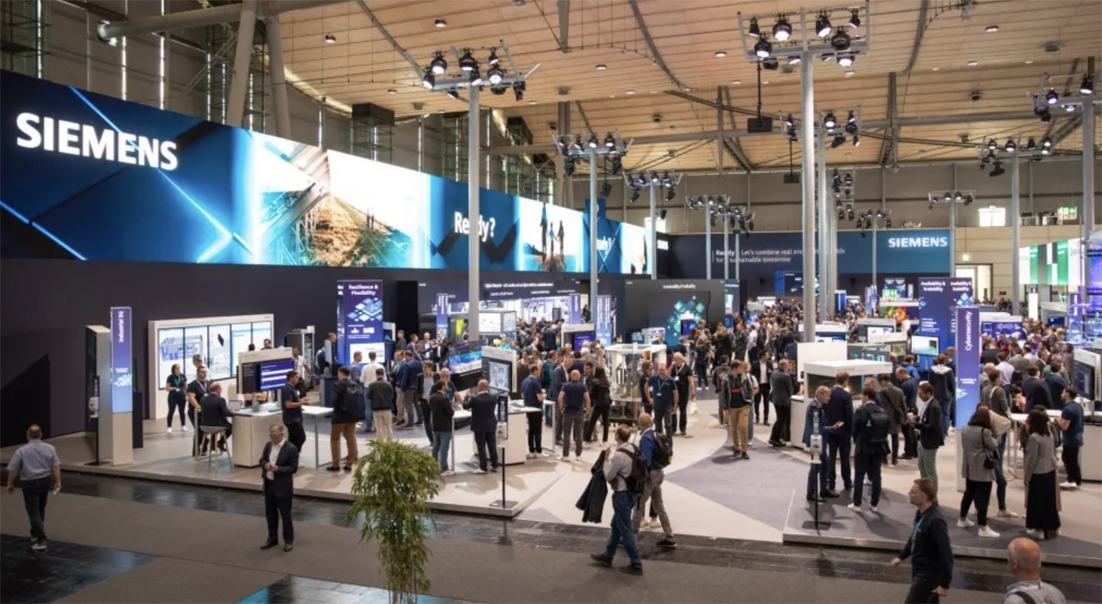

Siemens smartens industry and buildings at Hannover Messe

- April 24, 2023

- Steve Rogerson

At last week’s Hannover Messe, Siemens premiered Industrial Operations X for flexible industrial processes, plus new use cases with Building X, a scalable digital platform for buildings,

“The next step in the digital transformation is the industrial metaverse: a model of the real word – and of all its physical characteristics – that is always online,” said Roland Busch, CEO of Siemens. “People can collaborate in real time to continuously optimise the virtual world. In this way, we make the real world better, more efficient and, in particular, more resource-efficient.”

Siemens’ presence at Hannover Messe focused on innovations and offerings for all aspects related to the Siemens Xcelerator digital business platform. This platform, which launched last year, has grown and developed continuously ever since. At its core is a curated portfolio of IoT-enabled hardware and software. Together with a partner ecosystem and a marketplace, Xcelerator supports companies in their digital transformation.

With Industrial Operations X, Siemens is setting a benchmark with a range of products and services for industry. These offerings combine operational technology (OT) with integrated information technology (IT). IT technologies are brought to the shopfloor with a new level of modularity: low code, edge, cloud computing and the IoT combined with automation technology and digital services.

This open and interoperable portfolio should further accelerate production processes, which are already well automated. The result will be a more adaptive form of manufacturing that is also more autonomous and, at the same time, people centric.

“The whole world loves IT, but the world runs on automation that uses operating technology, or OT,” said Cedrik Neike, member of the managing board of Siemens and CEO of Digital Industries. “By combining the real and digital worlds like no other company, we make our customers faster, more adaptable and more ecofriendly.”

Siemens also presented Building X and its cloud-native applications Energy Manager, Security Manager and Operations Manager. These applications have been designed to support high-performance, safe and sustainable buildings in various environments, including production and manufacturing sites and commercial buildings.

Building X is built on Xcelerator design principles as a modular, fully cloud-based, open smart-building platform. It features artificial-intelligence-enabled applications, connectivity and built-in cyber security.

Building X can be used as a software-as-a-service (SaaS) application, on a subscription basis, or users can opt for an end-to-end offering of building services. With Building X, Siemens aims to create the industry’s most open digital platform for buildings, a platform that lets users benefit from enhanced built environments and services to make intelligent decisions about their buildings, assets and workforce.

“The digitalisation of buildings, grids and electrification infrastructure is key to driving a smarter, more efficient and decarbonised industrial sector,” said Matthias Rebellius, member of the managing board of Siemens and CEO of Smart Infrastructure. “At Hannover Messe, we are demonstrating how the combination of software from our Siemens Xcelerator portfolio and hardware enables our customers to improve the performance of commercial buildings and industrial facilities, lower costs, and reduce environmental impact to futureproof their businesses.”

Siemens also revealed its latest switchgear innovation for primary distribution networks using vacuum-interrupter technology and clean air as an insulating medium with a global warming potential (GWP) of less than one.

As a result, this is climate friendly and free of fluorinated gases. For key functionalities, this switchgear has integrated sensors that can be connected to software from the Xcelerator portfolio.