Siemens partners Materials AI specialist Citrine

- March 17, 2021

- William Payne

Citrine, a Californian manufacturing software company specialising in the materials and chemicals sectors, is partnering with Siemens Digital Industries Software. The partnership aims to develop new digital solutions to help materials, chemicals, and product development companies accelerate development, incorporate AI, and expand materials design functionality within product simulation.

The partnership will integrate and expand capabilities of the Citrine platform with Siemens Opcenter research, development and laboratory software, as well as Siemens Simcenter product simulation software.

Opcenter supports data management, specification management, formula development, experiment management, and production process design. Together, Opcenter and the Citrine Platform will let customers access domain-specific AI to identify and develop new formulations that meet customers specs, address market needs, and adapt to regulatory and supply chain shifts.

“Most clients have multiple databases for specification data and multiple disconnected lab systems,” said Zvi Feuer, senior vice president for Digital Manufacturing Software at Siemens Digital Industries Software. “Data is collected, but not in context and certainly not in a method that is easy to re-use for AI. Opcenter RD&L offers the foundation for successful material-aware AI when used with the Citrine Platform. It allows users to drastically reduce the number of iterations needed in age-old product development cycle of develop draft formulation, create the prototype, test, enhance formulation, create new prototype, test again. Without documenting and tagging previous experiences like with Opcenter RD&L, AI cannot be effective.”

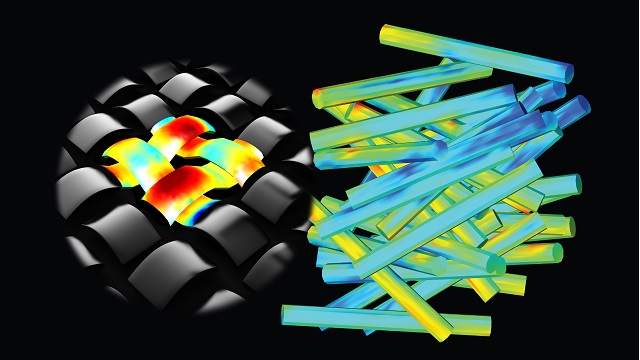

Siemens’ Simcente software is a portfolio of predictive product simulation and test tools, including CAE simulation, system simulation, and physical testing tools. Using these product simulation tools with the materials-aware AI capabilities of Citrine Platform, product developers can integrate materials design with product simulation.

“Materials selection decisions have traditionally been made based on data reported in static material data sheets, preventing materials and product companies from bringing to market optimised, high-performance products,” said Jan Leuridan, senior vice president of simulation and test solutions for Siemens Digital Industries Software. “By fusing the material and product engineering with the combination of the Citrine and Simcenter product portfolios, we can enable AI-driven Generative Materials Engineering, transforming materials from a constraint to a degree of freedom in part design and optimisation. This AI-driven materials customisation is nothing short of a paradigm shift. For the first time, materials development can progress at the same pace as engineering innovation.”

“The future of the materials and chemicals industry will be driven by digital tools that unlock agility and development speed,” said Greg Mulholland, CEO and co-founder of Citrine. “Strategically partnering with a leader like Siemens allows both companies to better serve our customers and deliver software solutions that unlock new capabilities through our partnership. We’re helping researchers, product developers, and business leaders accelerate innovation through the combination of data management tools, product and system simulations, and AI.”