GE applies AI to gas turbine design

- July 14, 2020

- Steve Rogerson

GE researchers are using artificial intelligence (AI) and machine learning (ML) to improve the design of gas turbine aerodynamic components.

The project aims to achieve a 30 to 50% reduction in design cycle times, or from one year to a few months. The company has partnered with the University of Notre Dame and GE Gas Power on the project.

The hope is that the emerging digital toolset will help push combined cycle power plant efficiency to new heights.

Aiming to let performance metrics be the principal driver in the design of cleaner, more efficient aerodynamic energy systems, GE Research has been awarded the first phase of a two -year, $2.1m project through Arpa-E’s Differentiate (design intelligence fostering formidable energy reduction and enabling novel totally impactful advanced technology enhancements) programme to build an AI-driven invertible neural network that can translate these metrics into optimised designs.

Today, complex aerodynamic energy components such as gas turbine blades have extremely long design cycle times of more than a year that require compromise between cost, performance and reliability. The researchers, together with GE’s Gas Power business and the University of Notre Dame, are aiming to develop and demonstrate an AI and ML- enabled design framework that takes half the time and is dictated almost entirely by the desired performance metrics. This could take the design of aerodynamic energy components to a new level.

Sayan Ghosh, project leader, said the team was building a probabilistic inverse design machine-learning framework – Pro-ML Ideas – which uses an AI-driven invertible neural network to overcome multiple design iterations and challenges that typically require engineering expertise across many complex functional spaces.

“This will essentially create a paradigm shift in gas turbine design by enabling us to explore and discover new learning curves not previously possible,” Ghosh said. “We believe that the Pro-ML Ideas, powered by AI and ML, will allow us to break free from the traditional design constraints and let us achieve more optimal designs in significantly less time versus the current state of the art.”

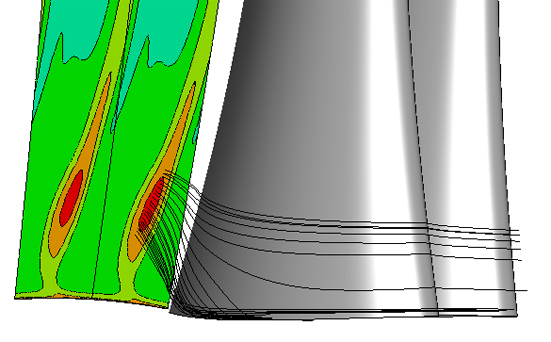

Pictured is a computational fluid dynamics model predicting the flow trajectory and resulting losses through the hub of a gas turbine blade.

“One of the chief reasons GE Gas Power has set world records in combined cycle gas turbine efficiency, is the design of more efficient aerodynamic parts and components,” said Ghosh. “With the integration of new AI-powered digital solutions like our invertible neural network being supported through Arpa-E’s Differentiate programme, we will be well on the path to achieving 65% efficiency and beyond.”

GE’s HA gas turbine technology has helped deliver two world records, one for powering an efficient combined cycle power plant, based on achieving 63.08 per cent gross efficiency at Chubu Electric Nishi-Nagoya Power Plant Block-1 in Japan, and another for helping EDF’s Bouchain Power Plant achieve 62.22 per cent net combined cycle efficiency in France.

With the GE Research and Gas Power teams, researchers from the University of Notre Dame team led by Nicholas Zabaras will bring more than 30 years of experience solving tough inverse design problems. Zabaras’s work in the area of regularisation techniques, high-dimensional Bayesian inverse methods, Gaussian process models for inversion, and most recently the integration of deep learning and inversion tasks will accelerate learnings on this project.

The end goal of the two-year project is to create an inverse design process to optimise the design of a gas turbine blade component and reduce the design cycle time. In future, the framework will also be extended to other applications such as aviation turbine engines, aeroderivative engines, wind turbines and hydro turbines.