Oracle helps tackle supply chain problems

- October 13, 2020

- Steve Rogerson

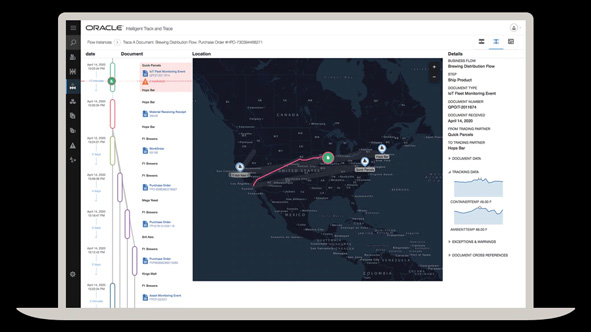

So organisations can build resilient and agile supply chains, Oracle has updated its Fusion Cloud Supply Chain & Manufacturing (Cloud SCM) to help users increase collaboration across supply networks, proactively manage supply chain assets, and implement long-term supply chain planning.

“The last 12 months have stretched supply chains to the limit as organisations wrestle with the disruptions of Covid-19, shifting global trade agreements, rapidly changing customer expectations, and numerous other unforeseen circumstances,” said Rick Jewell, senior vice president at California-based Oracle. “With the new capabilities within Oracle Cloud SCM, we are helping our customers navigate this complexity and build more adaptable businesses that can respond to today’s challenges and whatever comes next.”

With Cloud SCM, organisations can identify new opportunities, rethink processes, and plan and execute across the entire business. The latest features and capabilities within Cloud SCM include:

- Logistics digital assistant: Provides on-the-go access to real-time supply chain information through a conversational interface that responds quickly, improves user satisfaction and increases business efficiencies. In addition, users can now easily access order status and shipment tracking remotely without having to navigate through the Oracle Transportation Management application or understand complicated data mappings. As a result, a supply chain manager can be informed of all in-transit orders and receive timely updates on shipments from anywhere, on any mobile device.

- AI planning advisor: Uses artificial intelligence capabilities embedded within supply chain planning application to display recommendations that optimise new product introduction and enable users to respond to current and anticipated production disruptions.

- Field service preventative maintenance: Helps organisations improve the customer experience through preventative service flows and break-fix and installation capabilities that are delivered via the service logistics cloud for field service.

- Multi-tier supply chain collaboration: Delivers improved visibility into upstream supply to increase overall supply chain responsiveness. Supply chain collaboration can now synchronise upstream supply information such as on-hand balances, purchase order details and work order details from multiple tiers of external organisations. The data are then automatically shared with the supply planning cloud.

- Planning for project-driven supply chain: Optimises supply planning for project-specific material requirements and execution of purchase, transfer and work orders, all with project and task references. By matching demand and supply based on flexible rules, users can group projects and plan at the group level when supplies can be combined across many projects.

- Channel revenue management capabilities: Streamline and optimise trade programmes by letting organisations create, resolve and settle claims for deductions and overpayments. In addition, the capabilities simplify the export of supplier programmes and claims.

- Cross-product procurement enhancements: Simplify integration with external systems to help users integrate and extend procurement processes via new and modified Rest APIs. The procurement cloud also has more deep links that provide navigation directly to application pages without using the menu structure. These links can be leveraged in various ways, including in business intelligence reports, notifications and third-party application pages.

The Oracle Cloud offers a complete suite of integrated applications for sales, service, marketing, personnel, finance, supply chain and manufacturing, plus automated and secure infrastructure featuring the firm’s autonomous database.