BMW blockchain tracks international supply chains

- April 8, 2020

- imc

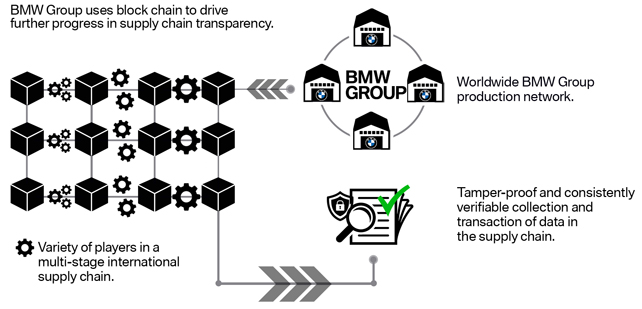

BMW is using blockchain technology to achieve traceability of parts and critical raw materials in complex international supply chains.

The German car maker is using the digital technologies to optimise its processes. Blockchain, a technology that enables tamper-proof data sharing, has potential applications throughout the entire automotive value chain. BMW is using this technology in purchasing to ensure the traceability of components and raw materials in multi-stage international supply chains.

“In 2019, we conducted a successful pilot project for purchasing front lights,” said Andreas Wendt, member of the management board at BMW. “This year, we want to expand the project to a large number of other suppliers.”

The automotive industry’s international supply chains are highly complex. They generally involve numerous players at different delivery stages and often undergo rapid changes. For this reason, considerable effort can be needed to track a component’s origin or supply route clearly, for instance.

Until now, it has been customary for the many partners to manage their own data separately. The companies’ respective IT systems have not always been able to communicate consistently with one another. For BMW’s purchasing experts and its suppliers, ensuring transparency therefore involved considerable manual effort.

BMW thus initiated the PartChain project to ensure seamless traceability of components – more or less at the push of a button – and provide immediate data transparency in complex supply chains for all partners involved going forward.

“PartChain enables tamper-proof and consistently verifiable collection and transaction of data in our supply chain,” said Wendt.

In 2019, the pilot project focused solely on part tracking. In the long term, BMW also expects the project to enable complete traceability of critical raw materials – all the way from mine to smelter.

“This move is designed to take the digitalisation of purchasing at the BMW Group to the next level,” said Wendt. “Our vision is to create an open platform that will allow data within supply chains to be exchanged and shared safely and anonymised across the industry.”

PartChain uses cloud technologies including Amazon Web Services and Microsoft Azure in addition to blockchain technology. This allows the origin of components to be tracked between all participating partners without any risk of manipulation. The 2019 pilot project already involved two of BMW’s total 31 plants – Spartanburg in the USA and Dingolfing in Germany – as well as three locations of the automotive lighting supplier. This year, the platform will be rolled out to about ten suppliers.

An industry-wide system would let all partners participating link their business processes more closely and coordinate between companies. However, common standards and control models are needed to leverage the full potential of an open platform.

BMW therefore co-founded the Mobility Open Blockchain Initiative (Mobi) in 2018, a cross-industry initiative comprising 120 automotive, mobility and technology companies. Within Mobi, the company heads a working group on supply chain issues. Mobi members’ shared objective is to help blockchain technology break through in the mobility sector.

“We want to share our PartChain approach with the initiative and invite interested companies to join the initiative,” said Wendt.