Volterio robots aid electric vehicle charging

- April 7, 2020

- imc

Austrian company Volterio has developed an autonomous robot to charge electric vehicles and stop city street being littered with charging stations.

Charging stations can be an eyesore in inner cities, and the bulky cables and plugs can also be an inconvenience in people’s garages. Contactless inductive charging with coils embedded in the garage floor or the road surface has none of these visual or mechanical annoyances.

But unfortunately it comes at a heavy price, and in more than one way: making the coils disappear means the ground has to be opened up and refinished; the maximum output is currently 3kW in most cases, which can result in long charging times; and with this type of charging, a significant portion of the power is lost compared with plug-in cables. This loss is even higher if the car is not parked right over a coil.

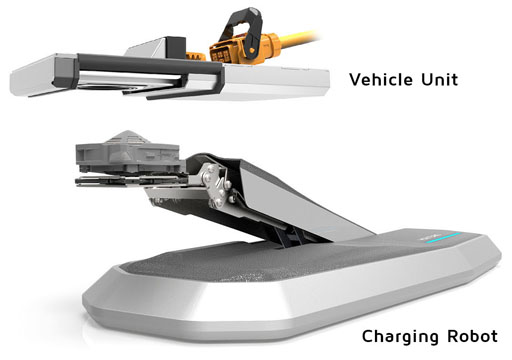

The technology from Volterio offers an elegant solution to all of these problems. When inactive, the charger is an inconspicuous, only 6cm high structure on the floor. The car is then parked over it for charging. Next, a robot arm extends telescopically. At the end of this arm is a connector that seeks its counterpart on the car’s underbody.

The two components have previously exchanged information with each other via encrypted wireless communication. And since the conical-round current carrier is not a connector in the traditional sense, it is still able to make full contact even if the car is not parked in the optimal position. An ultrasonic system is used to make sure the arm accurately finds its target. The connection is established in less than 15s.

The connector must simply be within a range of 50 by 50cm, and the car can even be parked at an angle. It is also possible to embed the entire unit in the floor for new constructions of garages or parking spots.

The charging capacity of a charger with home connection is 22kW, which means that even the largest car batteries can be fully charged in four to five hours. The technology itself is designed to handle up 100kW DC, which lowers the charging time to an hour.

The idea behind Volterio stems from a master thesis that Christian Flechl wrote in 2014 at the Graz University of Technology in Austria. Today, he is the managing director of Volterio, and his product is about to go into series production.

An important aspect in the development of the prototype was the three motors that move the robot arm along the three axes.

“We wanted to build a device that was as flat as possible, so there was very little space available from the beginning,” Flechl said. “At the same time, we need to move considerable weight. So the motors – in conjunction with the appropriate gearhead – have to offer high torque, high speed and be small in size.”

A search on the internet quickly led him to German company Faulhaber, as not many companies are able to meet these types of specifications.

“In talks with other experts, I was reassured that Faulhaber was the way to go, and that became even more evident when we started working together,” said Flechl. “Faulhaber sponsored the entire project with extensive technical advice, selecting the right motors, and by offering the motors themselves.”

DC micromotors with planetary gearheads and a suitable motion controller were installed in the prototypes. In addition to that, Faulhaber selected and provided other drives for testing purposes.

The high motor performance of the CR series is based on a stable graphite commutation with low wear, neodymium magnets, and a particularly high ratio of copper in the winding. The charging station is designed for about 20,000 cycles. This means only about 1% of the service life of the drives is used. Their robustness is also very important, because the Volterio units must work reliably even after long standstills and in harsh weather conditions.

The prototype performed well in testing. Volterio is now working on new challenges:

“Automated charging processes can be used in many different ways,” Flechl said. “This is true for the entire field of logistics as well as for all driverless vehicles. Solutions for electric trucks are under development as well. We are developing suitable charging robots, and we continue to rely on the valuable support of Faulhaber.”