Winvic project uses IoT to track construction site hazards

- October 5, 2020

- Steve Rogerson

UK firm Winvic is using real-time image and machine-learning technologies to detect, recognise and track hazards on its construction sites. This will then alert nearby operatives via IoT-enabled GPS devices.

This is part of an Innovate UK funded project that also involves the University of the West of England (UWE) in Bristol and One Big Circle.

Dubbed as Computer-Vision-Smart, the computer vision and IoT for personalised site monitoring analytics in real time project will run for two years.

The Big Data Enterprise & Artificial Intelligence Lab (Big-Del) at UWE and Bristol industrial intelligent video specialist One Big Circle are in the consortium that was successful in its application for an Innovate UK – the UK’s innovation agency – smart grant.

They will share the £600,000 research pot with Winvic. Smart grant is the new name for Innovate UK’s open grant funding programme. Innovate UK, part of UK Research & Innovation, is investing up to £25m in the best game-changing and commercially viable innovative or disruptive ideas through its open grant funding programme.

Interior and exterior site cameras will continuously capture video images. Via artificial intelligence (AI), any hazards – from moving heavy machinery to overhead works to people operating without the correct personal protective equipment (PPE) – will be identified.

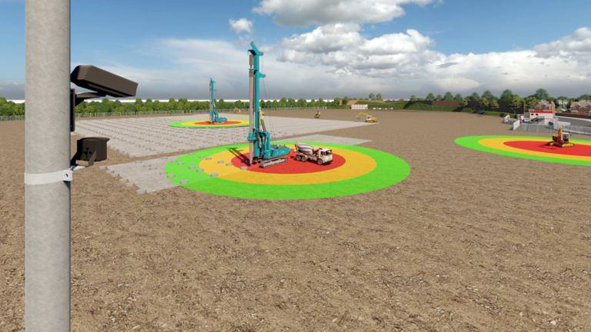

Over the length of this project, the machine-learning models will be able to make an increasing number of intelligent predictions over the time of the project. Safe space radii, or zones, will be predetermined and applied to each hazard. Exact operator and hazard locations will be understood through a geographic information system (GIS).

When an operator enters a hazard zone, the individual – and when appropriate other members of the site team – will receive a personal alert via an app on a wearable or mobile device. Managers can also review alerts and relevant video segments from a laptop-based app.

In the event of an operator being identified as not wearing appropriate PPE, the person and project manager will be alerted of the issue. Each hazard radii will comprise four zones (S-A-F-E):

- Safe: a site worker is in a safe location and won’t receive an alert;

- Alert: a site worker is alerted to a possible risk;

- Full alert: a site worker receives a consistent alert; and

- Escalate: there is a site wide alert of an immediate health and safety concern.

A clear need for the development and widespread use of digital technologies within construction health and safety was identified. Existing vision-based approaches to construction site monitoring only focus on areas such as site security, dispute avoidance and time-lapse project progress; applications to improve people’s safety are lacking.

Furthermore, HSEQ (health, safety, environment and quality) managers and operatives depend on self-reporting or warnings from co-workers, which can simply come too late to avoid an incident. Consequently to achieve a zero-harm target, health and safety best practice must be reimagined using effective digitisation alongside appropriate social interventions, delivering an overlap between social and technical systems.

Two Winvic project sites will take part in the initiative to develop the technology over the 24-month period.

UWE and Winvic are also partners on the Conversational BIM Project, another AI-enabled development to create a voice activated, BIM model connected headset, which will allow users to retrieve any and all project design and construction information with a simple vocal request.

“Utilising intelligent digital technologies in construction to deliver projects more rapidly, cost-effectively and safely is a passion of Winvic and this forward-thinking health and safety initiative is truly ground-breaking,” said Tim Reeve, Winvic’s technical director and leader of the project. “It’s a privilege to be working with UWE Bristol on a second AI-enabled project and, with One Big Circle also on-board, we have a very dedicated and eager consortium team.”

He said there was a clear gap in this area of construction safety, where social and technical efforts can successfully converge. With the technology, he said, would come better opportunities to reach the firm’s zero-harm aim.

“It’s a very exciting time in the world of digital transformation, and our achievements over the next two years will generate a significant leap forward for safety across the whole of the construction industry,” said Reeve.

Olugbenga Akinade, an associate professor at UWE, added: “This Computer-Vision-Smart project will enable us at the Big Data Enterprise & Artificial Intelligence Lab to employ our expertise in computer vision and sensor fusion technologies to improve safety on construction sites. The project is pivotal to our strategy to push the frontiers of construction research and to address industrial needs using innovative digital technologies.”

And founder and director of One Big Circle, Emily Kent, said: “As specialists in intelligent video and integration, our purpose is to provide digital video solutions to real world challenges, especially in industrial environments, thereby increasing safety and enhancing operations. The power of a collaboration such as the Computer-Vision-Smart group means we can steer our video and computer vision expertise according to industrial need, working closely with others who are also experts in their own fields. We have been successful with this approach in highways and rail previously and are very excited about working alongside Winvic and UWE in delivering this advanced capability in the construction industry.”