Ultrasound could make any surface Smart

- December 31, 2019

- imc

A San Francisco start-up has launched an ultrasound system-on-chip that would transform how and where smart devices could be used. UltraSense Systems claims its ultrasound SoC allows touch sensing through virtually any material and any thickness, and is immune to moisture, dirt, oils and lotions. It means that smart devices could be used far more easily in rain, and in heavy industrial, energy, emergency and agricultural environments. Smart device interfaces could also be embedded into industrial, domestic, automotive and medical appliances, and made far more robust and resilient.

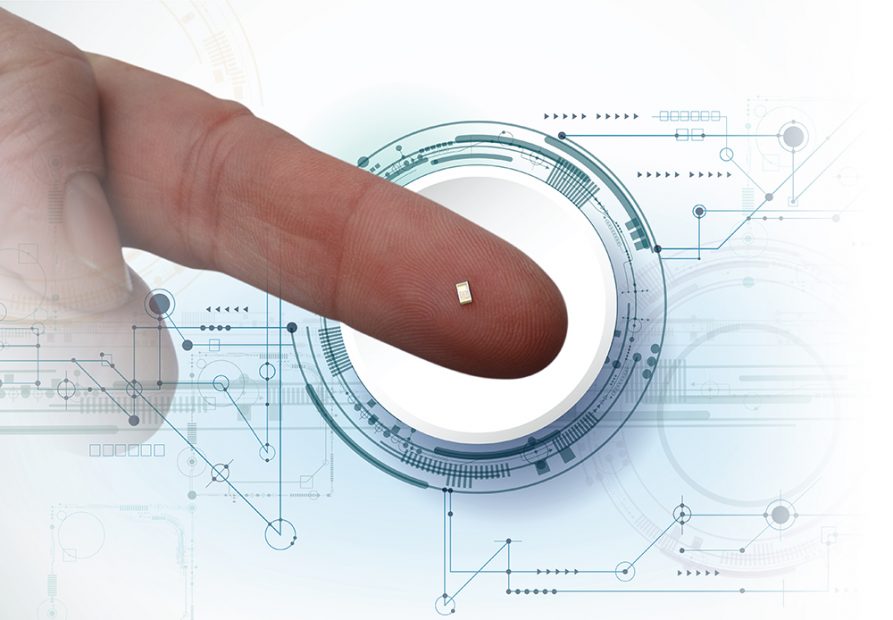

The company’s newly launched family of TouchPoint sensors is claimed as the world’s smallest ultrasound system-on-chip. The SoC is currently already sampling to smartphone makers. The size is 1.4 x 2.4 x 0.49 mm, about the size of the tip of a pen. The sensors are already production-ready, and are expected to be incorporated into consumer devices in 2020.

The company says that the technology allows a multi-functional touch interface to be achieved through virtually any material and any material thickness, including metal, glass, wood, ceramic and plastic.

TouchPoint sensors are designed to provide highly localised touch sensing from thin to thick surfaces with sensors in tiny package sizes and consuming mere uAs of current in always-on mode. TouchPoint sensors are designed to operate independent of a product’s host processor with all the algorithm processing embedded in the sensor. It can be used as a standalone power button, among other uses (volume +/-, shortcut keys, etc.) for wake-on-touch sensing, by powering on the entire product with a simple touch and can be a multi-functional user interface using a series of taps, holds and swipes. Sensors can be directly interfaced with power management and haptic driver ICs.

Using 3D Z-force ultrasound sensing provides gram-force measurement in applications that require gloves, external covers/cases and water/ice rejection. For applications where low power consumption is not a requirement, certain TouchPoint sensors include large drivers with higher operating voltages to transmit the ultrasound beam through very thick materials of solid metal (e.g. >25mm/1 inch) and beyond. The transducer can also be shut off and the sensor used to drive piezo materials to cost-effectively support large touch sensing areas, like a mouse-pad in a laptop or track-pad in an automobile centre console.

“We have seen a shift in the way we interact with our devices, where digital has replaced mechanical, and the move to virtual buttons and surface gestures is accelerating,” said Mo Maghsoudnia, founder and CEO, UltraSense Systems. “The use of ultrasound in touch user interfaces has not been implemented in such a novel way until now. Our family of TouchPoint ultrasound sensor solutions enable new use cases that allow OEMs to bring a differentiated user experience with a wider variety of touch and gesture functions under virtually any material and material thickness.”

“UltraSense TouchPoint ultrasound sensor is a unique and innovative addition to the list of solutions for user interface capabilities,” said Richard Wawrzyniak, principal market analyst for ASIC & SoC at Semico Research. “This gives industrial designers a really useful option to differentiate their products while improving performance without adding to clutter. Needless to say, the ‘cool’ factor in products that employ this technology is going to be very high. Semico thinks this product is going to very successful as designers discover what they can do with it.”

Potential use cases of the ultrasound SoC include:

- Removal of mechanical buttons from smartphones to support new industrial designs required for millimetre wave 5G phones

- One-hand selfie operation with a multi-functional touch user interface on the backside of the smartphone

- Gaming buttons and photo-taking keys seamlessly built into the sides of smartphones

- Touch interface or slider in wearable devices like watches, earbuds or AR/VR glasses

- A new ubiquitous touch user interface across home appliance products that use a variety of thick materials from stainless steel, glass, plastics and ceramics

- The ability to open or lock your car door with a simple touch of the metal chrome plated door handle

- Virtual buttons located in the steering wheel centre and door panels using solid surfaces that are easy to clean in ride-sharing and shared vehicles