Libelium controls salinity on mussel and salmon farms

- July 14, 2021

- Steve Rogerson

Two smart water projects in New Zealand are using technology from Spanish IoT firm Libelium to control salinity for mussel and salmon farming.

Since aquaculture took off in New Zealand in the 1980s, it has grown from strength to strength. The main products are greenshell mussels, pacific oysters and king salmon. The industry exports to 81 countries with annual sales of around $500mn.

Adroit, distributor of Libelium smart water technology in New Zealand, is helping producers achieve sustainable aquaculture standards. Two of Adroit’s most recent projects are helping salmon and mussel producers meet standards of sustainability, quality and efficiency.

Mussel farm operators are constantly needing to test the quality of the water and take samples of their products. This is to meet compliance requirements for harvesting standards set by the Ministry for Primary Industries (MPI). These standards establish a minimum level of salinity for all harvesting.

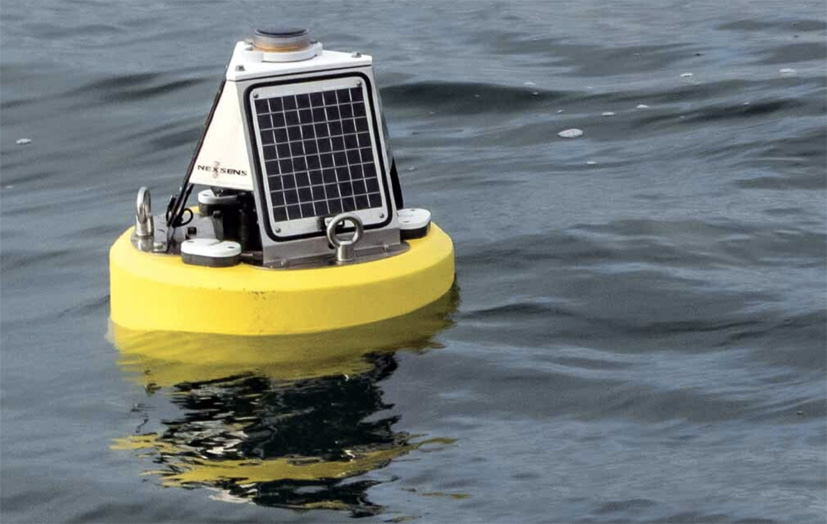

To increase harvest times and maintain large mussel harvests, New Zealand farm Westpac Mussels is using a floating buoy designed by Adroit. The buoy features the Libelium Smart Water board and sensors that monitor the salinity of the water in real time.

The rainy periods of weather in the surrounding areas of the farm affect the salinity of the sea. When it rains heavily, runoff reaches the ocean and, finally, the aquaculture farm. Since mussels are filter feeders – they can filter about 20 litres of water per hour – they absorb everything in the water, salinity included. When this reaches the maximum level set by the MPI, farmers must stop harvesting immediately, since the mussels are no longer fit for human consumption.

Currently, farmers rely on rain gauges to warn them of potential salinity level problems. However, these gauges are installed on the mainland, sometimes up to 50km away from the farm. So, if the salinity levels of the run-off are high in the area where the rain gauges are located, it can mean the closure of the farm, located offshore, for up to five days. This is a waste of harvesting time and potential profit because the salinity has not yet changed on the farm as water changes take a few days to reach the deep sea depending on the tides. During this time, the mussel is still fit for consumption and can be harvested.

Therefore, Westpac Mussels sought to improve both the speed and accuracy of collecting meteorological information and salinity data to avoid any unnecessary farm closures.

With this in mind, Adroit designed a buoy that met the farm’s key requirements:

- Real-time, accurate and reliable salinity data, viewable through a web browser and mobile app

- Alert data to notify farms when salinity falls below regulated levels

- The possibility for MPI to collect data through APIs to satisfy reporting requirements

- A robust industrial system capable of withstanding marine conditions

- Less maintenance required for general antifouling and sensor cleaning and calibration

Considering farms are often located in largely remote areas, network connectivity can be difficult.

The Adroit data buoy real-time monitor has a Libelium Smart Water board inside. Adroit can integrate in-situ sensors to measure temperature, conductivity and salinity. Each buoy has a Libelium board that transfers data over the Spark Cat-M1 network using NB-IoT connectivity to the Adroit platform. Westpac Mussels can access this platform through a web browser or mobile app and create customisable dashboards, reports and email alerts.

The data are exportable via a CSV file or APIs within existing business applications. It is through this API that the salinity levels at the farm site are communicated to the MPI to continue harvesting even though on the mainland the rain gauges may warn of high salinity.

Something similar happens with salmon. Salmon farming is an important asset of the New Zealand economy and is heavily regulated and protected, so any innovation applied to its cultivation is welcome, but also closely monitored.

Farming began in the late 1980s and today New Zealand produces 75% of the world’s king salmon, also known as Chinook salmon. This is tiny on the world scale though, accounting for less than 1% of the global salmon supply.

New Zealand King Salmon is a producer with over 30 years of experience growing and processing this unique breed of salmon. The firm cares for salmon throughout their life cycle in more than 61,000 hectares of the sea in the Marlborough Sounds.

King salmon require a unique diet for optimal health and growth. The main components of the food are complex fats, quality proteins, carbohydrates, essential vitamins and minerals. Underwater cameras on New Zealand King Salmon farms closely monitor appetite and activity during each meal.

In addition to controlling feed components and appetite, it is important to keep the salinity of the water stable within parameters when feeding salmon.

To do this, Adroit installed a water quality control system that allows this salmon producer to have a complete picture of everything that happens on its farms, in real time. For this, Adroit used Aqualabo dissolved oxygen and salinity sensors from Libelium’s Smart Water Xtreme. The sensors are placed at two depths, 25 and 50 metres deep. This allows a better understanding of the environment in which the salmon are moving.

At the time of feeding, the salinity of the water drops considerably. The King Salmon team receives an alarm at certain levels, as this drop could lead to a decrease in the quality of the fish.

These alerts travel from the Libelium sensor to Adroit dashboard via Vodafone’s Cat-M connectivity.

“Not only do we have immediate information, but we can also consult the history, extract the data and compare them over time,” said Kim Hooper, King Salmon business and planning analyst. “It is very valuable information for business intelligence.”