PICMG progresses industrial IoT standards

- June 28, 2022

- Steve Rogerson

Embedded computing standards body the PCI Industrial Computer Manufacturer’s Group (PICMG) announced at last week’s Embedded World in Nuremberg significant progress on its industrial IoT family of specifications.

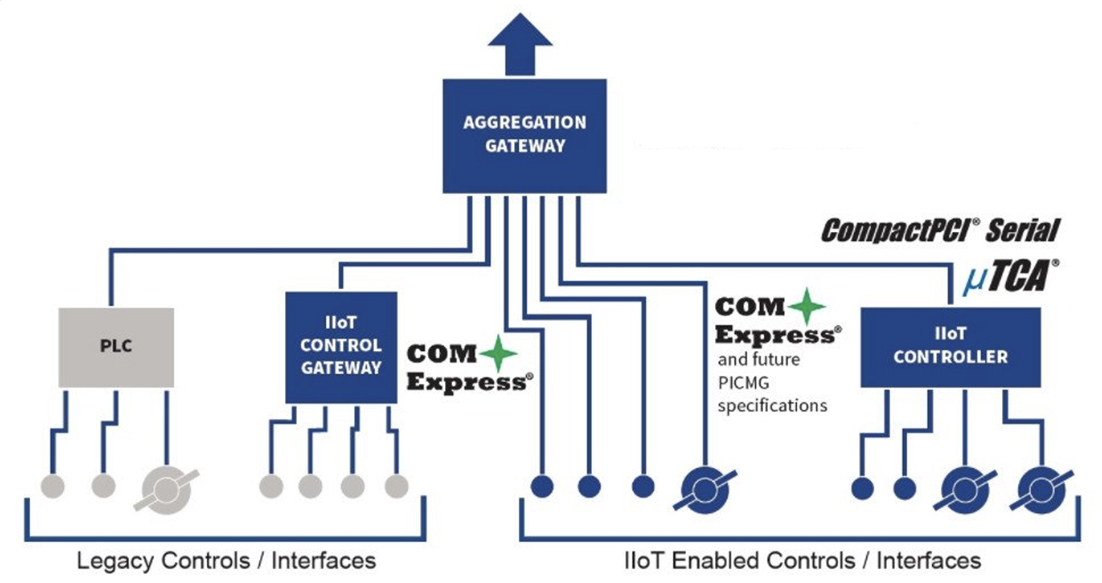

Highlighted by the IoT.1 firmware interface and data modelling specification and soon-to-be-ratified IoT.2 network architecture, ongoing efforts promise to abstract low-level device physics such that sensor node data become interoperable across all levels of smart factory deployments.

“When we first started looking at IoT, we found it fitted well with our existing knowledge of industrial automation,” said Doug Sandy, CTO of PICMG. “IoT is not just adding sensors or having analytics. It is about improving the effectiveness of the factory floor.”

However, he said one impediment to deploying industrial IoT was a lack of standardisation.

PICMG IoT.1 focuses primarily on a data abstraction layer that allows users to turn traditional sensors and effecters into plug-and-play smart sensors and effecters using free and open-source tools that require little-to-no programming expertise.

For example, the PICMG IoT Configurator and IoT Builder tools are reference implementations for building and generating smart sensor firmware that can be read by any sensor or controller.

The separate but complementary IoT.2 network architecture specification defines the integration of these smart sensors and effecters, as well as their data, into larger Industry 4.0 systems of systems.

Based on the Data Management Task Force’s (DMTF’s) Redfish API, the IoT.2 spec outlines an abstraction layer and transactional model so sensor and effecter endpoints can be monitored and managed in the context of job models similar to those available from major cloud service providers.

In other words, the data transparency afforded by the two specifications permits IT factory personnel to send specific, state-based jobs to a machine or clusters of machines in the pursuit of a desired outcome.

“IoT.1 provides low-level visibility of physical device parameters that can directly impact the quality and efficiency of your production line,” said Sandy. “IoT.2 provides an IT-like interface for managing both machines and jobs at a high level of abstraction. When used together, they support the analytics required for higher levels of productivity and throughput across a factory environment.”

He said an important part of the standard was allowing what-if testing using digital twins.

“This means creating a virtual model of the factory itself to find what changes you can make on a trial-and-error cyber model rather than the physical model,” he said.

To foster an environment of openness and collaboration, IoT.2 will not be exclusive of other existing IoT communications protocols and models and allows them to be converted to maintain compliance with the new spec.

IoT.1 was developed in collaboration with PICMG members Arroyo Technology, nVent, Triple Ring Technologies and Sandy Systems.

Founded in 1994, PICMG is a non-profit consortium of companies and organisations that collaboratively develop open standards for telecommunications, military, industrial and general-purpose embedded computing applications. There are over 140 member companies.

“Bringing in open standards speeds time to market,” said Jessica Isquith, PICMG president. “There is also the benefit of collaboration. When you work together, you end up with a better product.”