Nikon to drive Hybrid Manufacturing adoption

- September 20, 2022

- William Payne

Japanese optical tech specialist Nikon is expanding its next generation manufacturing programme with increasing development and adoption of hybrid manufacturing. Nikon is a major precision manufacturer, including of advanced precision manufacturing tools. Hybrid is an approach that combines digital manufacturing technologies, additive and conventional CNC manufacturing. It complements both conventional and AM, capturing the agility and speed of AM and the precision and finish of CNC.

To further its integration and development of hybrid manufacturing technologies into its manufacturing and capital equipment products, Nikon is investing in Hybrid Manufacturing Technologies, an additive manufacturing specialist that has created an approach to integrate additive tools onto any platform. Its technology allows users to unify multiple complementary technologies in one set up.

Parts manufacturers will often use AM processing and machining in tandem, depending upon their specific production goals and tolerances. Hybrid combines the flexibility of additive with precision and surface finish capabilities of CNC.

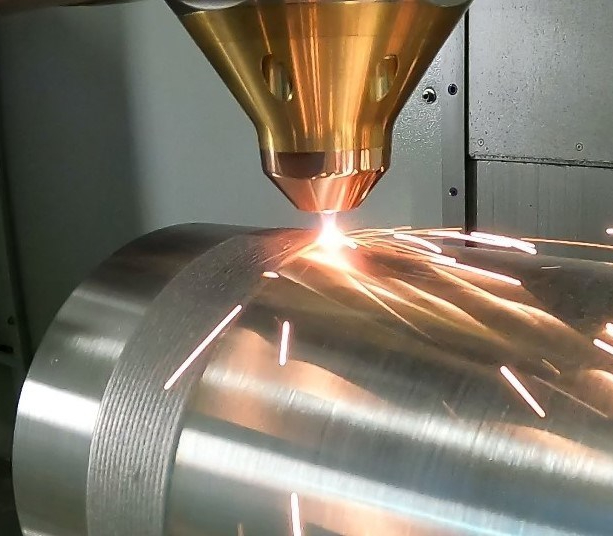

HMT AMBIT deposition heads require only a tool change to switch from cutting to adding metal. HMT’s tool changeable heads include laser processes as well as numerous materials and deployment methods. Its systems can upgrade existing vertical platforms to enable both additive and subtractive machining capabilities in one system or create bespoke solutions with customised heads for different manufacturing requirements.

Nikon manufactures precise equipment, with its products being used in applications ranging from semiconductor manufacturing and mass production of panels for televisions and smart devices, to medical systems, automotive and satellites. Nikon established the Next Generation Project Division to accelerate the launch of new growth businesses, including advanced materials processing technologies.

The investment in HMT is aimed at allowing both companies to accelerate innovation and expand hybrid manufacturing adoption. Yuichi Shibazaki, General Manager of the Next Generation Project Division said, “This investment in HMT is the latest component of our Next Generation Project programme to further industrialisation of digital manufacturing. As an industry leader with demonstrated collaborative capabilities, HMT and its AMBIT portfolio are well-matched with Nikon technologies. We look forward to working with them as part of our commitment to creating value and advancing society through novel industries like hybrid manufacturing.”

Dr Jason Jones, HMT CEO, said, “We are honoured to receive investment from such a longstanding technology leader as Nikon. Together we will more fully deliver on the promise of additive and digital manufacturing. We expect the results of this technology will touch the lives of virtually all people on earth in the coming decades.”

“Hybrid is all about synergy,” Peter Coates, HMT CTO said. “For the better part of ten years in this industry we have taken pride in the strategic nature of our collaborations and our partnership with Nikon takes this to a whole new level by adding value to advanced manufacture.”