Aegis MES automates personalised manufacturing

- September 30, 2020

- William Payne

MES vendor Aegis has extended its FactoryLogix platform with new digital twin, automated personalised manufacturing, and shop floor instruction authoring capabilities.

The platform now offers digital twin capabilities for PCB and mechanical computer aided design. The platform provides hundreds of electronic CAD, mechanical CAD and product lifecycle management formats. Users can employ animated 3D CAD mechanical models in both shop-floor operator instructions and data collection. According to Aegis, this results in a “truly intelligent digital twin”.

FactoryLogix also now provides adaptive machine recipes for automated personalised manufacturing. Dynamic recipes can be dispatched to machines based on the build configuration of a personalised product. Aegis says this enables “true single-piece flow of unique products in a fully automated way” and eliminates the high overhead “one recipe for one process” approach.

The new extensions to FactoryLogix further accelerate its shop-floor instruction authoring capabilities. An integrated photo capture feature can automatically build instructions on the factory shopfloor.

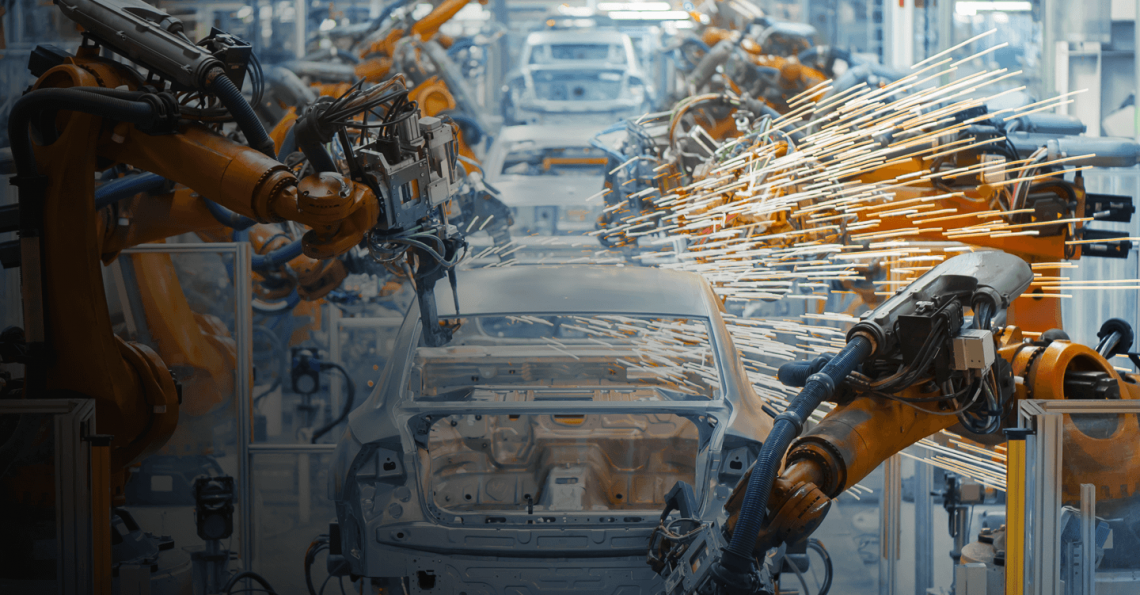

“Building upon the robustness that comes from two decades of evolving our MES IIoT-based platform, these two new releases add fresh capabilities fuelled by continual collaboration with our global customer base of complex discrete manufacturers in the military, aerospace, electronics, medical, consumer, and automotive industries,” said Jason Spera, CEO, Aegis Software. “As manufacturers face the changing and challenging environment, they continue to seek innovative solutions to support the need for continual process improvement, on-demand adaptability, smarter decision-making, and a heightened focus on employee productivity and satisfaction.”