Innodisk introduces FPGA Machine Vision platform

- November 29, 2022

- William Payne

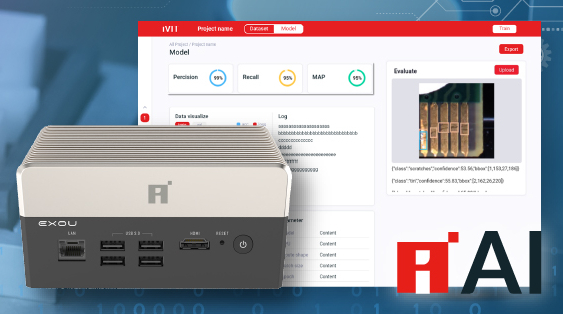

Industrial informatics provider Innodisk has launched an FPGA Machine Vision platform designed for smart factory applications. Powered by AMD’s Xilinx Kria K26 System on a Module (SOM), Innodisk has positioned its FPGA Machine Vision Platform for industrial system integrators aiming to develop machine vision applications.

The company has earmarked automated defect inspection as a key application for its new industrial machine vision platform. The deployment of an AI-powered machine vision platform can automate part inspection, increasing accuracy, removing error, and cutting an average of three seconds per part from the production process.

Innodisk’s FPGA Machine Vision Platform comes with 1GbE LAN, 4 USB 3.1 Gen1 ports, 2 M.2 slots, and a series of other expansion and connectivity options. With 0° to 70 °C operational temperature support, and optional industrial temperature support from -40° to +85°C, the platform can be deployed in harsh industrial environments. Featuring support for Innodisk’s InnoAgent out-of-band remote management module, the platform can be remotely managed from anywhere, including during a system crash or an in-band network failure.

The suite includes an FPGA Model Zoo, as well as Innodisk’s in-house software solutions, such as iCAP (Innodisk Cloud Administration Platform), and iVIT (Innodisk Vision Intelligence Toolkit). iVIT for example, provides a deep learning environment for efficient development and deployment of “no-code-operation” solutions.