Atos brings Renault inhouse IIoT to market

- July 25, 2022

- William Payne

Renault Group and Atos have launched a service to collect and analyse manufacturing data at enterprise scale. The ID@S service allows scaled-up standardised data collection across the entire production and supply value chain. The service was initially developed inhouse by Renault, where it is deployed at scale across the company’s manufacturing base, and has been productised for the market by Atos.

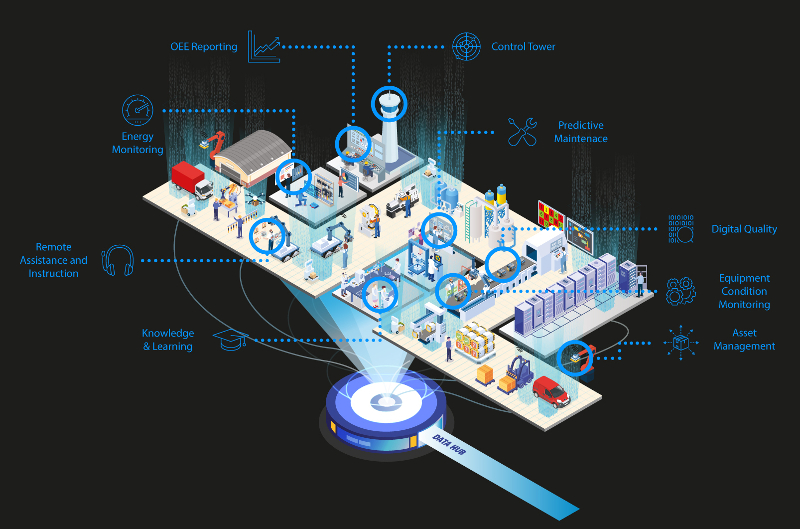

“ID@S” (Industrial Data @ Scale) is designed to allow manufacturers to collect and structure data from industrial equipment at scale to improve operational excellence and product quality. The software allows manufacturers to collect data from a wide range of manufacturing facilities (diverse suppliers, generations, global location, firmware updates, etc.) in a standardised and effective way, then contextualised and made available in the cloud. As a result, the data corrects and scales up production processes and product quality with immediate effect.

Access to standardised data via simple to use analytical tools and dashboards accelerates the deployment of many kinds of use cases (production, maintenance, quality, and energies, etc.), including net zero benefits. Additionally, with ID@scale, manufacturers can target significant energy consumption benefits by monitoring and optimising energy consumed on production lines.

As part of the company’s digital transformation strategy, Renault Group’s IT, digital and engineering teams developed the software to capture data from its manufacturing facilities. For each type of manufacturing process, data is collected and structured in a standardised way, enabling a variety of use cases across manufacturing, engineering, quality, CSR, logistics, etc. to be addressed.

At present, this solution is deployed at scale across twenty-two plants within the Renault Group. More than 7,500 pieces of equipment are connected, with standardised data models representing over 50 different manufacturing processes from screw-driving to aluminium injection, including car frame welding, machining, painting, stamping, in addition to new manufacturing processes for electric motors and batteries.

Renault Group is already saving 80 million euros per year and aims to deploy this solution across the remainder of its 35 plants, connecting over 22,000 pieces of equipment, by 2023 to generate savings of 200 million euros per year.

Software and services company Atos has modularised and industrialised Renault’s solution. The ID@scale service leverages Atos’ Edge to Cloud offering, enabling real-time analysis of large volumes of complex industrial data while securing it from the Edge to Cloud platforms, as well as optimising the inference of the most complex artificial intelligence models thanks to its Bull Sequana Edge server range.

“Renault Group has developed a unique technology solution to collect large-scale manufacturing data to improved performance of our production tools and therefore the quality of our vehicles. Today, we are pleased to announce a new milestone. Through our collaboration with Atos, we will go one step further in commercialising our expertise as we support manufacturing sector organisations in the scale-up of their digital transformation. This marks a new step in Renault Group’s digital transformation and innovation capacity,” said Jose-Vicente de los Mozos, EVP Group Industry, Renault Group.

“In a market with no equivalent solution, Atos modularises and enhances Renault Group’s initial solution for all manufacturing sectors, on a worldwide basis. By joining forces, Atos and Renault Group are enabling organisations to effectively collect data from their plants to leverage information on a large-scale basis and successfully scale-up and accelerate their digital manufacturing transformation.” said Rakesh Khanna, Head of Digital, Atos.