IoT Collaboration for Remote Concrete Hydration Testing

Many industries that utilize data or information are positively impacted by new developments made possible by the Internet of Things (IoT). Topping the list within these markets is modern engineering. While immediate impacts may be indirect, engineers can be assured that it will change how they design and manage building systems in the future.

CREATING INTELLIGENT SPACES: Five strategies to accelerate smart building transformation

The Internet of Things (IoT) is rapidly transforming the world, delivering connectivity and new experiences in our daily lives. In addition to changing everyday experiences, IoT also provides organizations with innovative ways to gain and apply data-driven insight. This digital feedback loop is fueling a new wave of improvements to operations, products, and experiences. As the benefits of IoT become more apparent, forward-thinking leaders are turning their attention to the spaces we inhabit. In offices, hospitals, schools, factories, and retail spaces around the world, building owners and their tenants are looking to increase energy efficiency, optimize space utilization, and improve productivity through IoT initiatives. Already, nearly 50% of developers, owners, and occupants believe that a smart building strategy will become a competitive differentiator in the commercial real estate market.1 And as smart buildings and spaces become more ubiquitous and interconnected, they pave the way for entire communities and smart cities built on a foundation of IoT-enabled insights.

Industrial plants use the newest protocols, IoT gateways and sensors to increase safety and improve plant efficiency

Opening or shutting a valve seems like a straightforward task, until that

valve is placed in an industrial environment, surrounded by chemicals,

machinery, high heat and dangerous equipment. In such an environment,

making a mistake can be disastrous. Thankfully, new communication

protocols and sensors are now available, eliminating the risk of mistakes by

hands-on workers performing more dangerous day-to-day operations

within industrial plants worldwide

How to catch water leakage before it catches you

Based in Sweden, IoT solution provider, iioote, which is a LoRa Alliance member, has developed a preventative solution that uses Semtech’s LoRa devices and wireless radio frequency technology. Semtech’s solution is composed of a widely adopted long-range, low-power solution for IoT that gives telecoms companies, IoT application makers and systems integrators the feature set necessary to deploy low-cost, interoperable IoT networks, gateways, sensors, module products and IoT services worldwide.

Illuminating Concepts Partners with MultiTech to Innovate OOD Lighting

Looking to take their lighting displays to the next level, the designers at Illuminating Concepts reached out to MultiTech to provide a top-of-the-line remote device management (RDM) solution to enhance the capabilities of their lighting arrangements.

Improve efficiency and throughput with seamless connectivity for intelligent exoskeletons

Introducing the intelligent power suit from German Bionic, underpinned by global BICS IoT connectivity. By combining human intelligence with machine power, the suit, worn on the body like a backpack, supports and enhances the wearer’s movements, reducing the risk of accidents and excessive strain. Embedded sensors and built-in IoT connectivity enable ongoing improvement and integration with smart factory systems.

C&D Mechanical Inc.: Industrial Plumbing

In less than a year’s time, C&D spent more than $20,000 to replace ProPress systems; which are tools used to connect pipes for commercial plumbing installations. The business needed an asset tracking system to monitor the use and location of these valuable company resources. An effective solution also needed to track the number of tools in circulation and the length of time out in order to minimize time in transit or inventory.

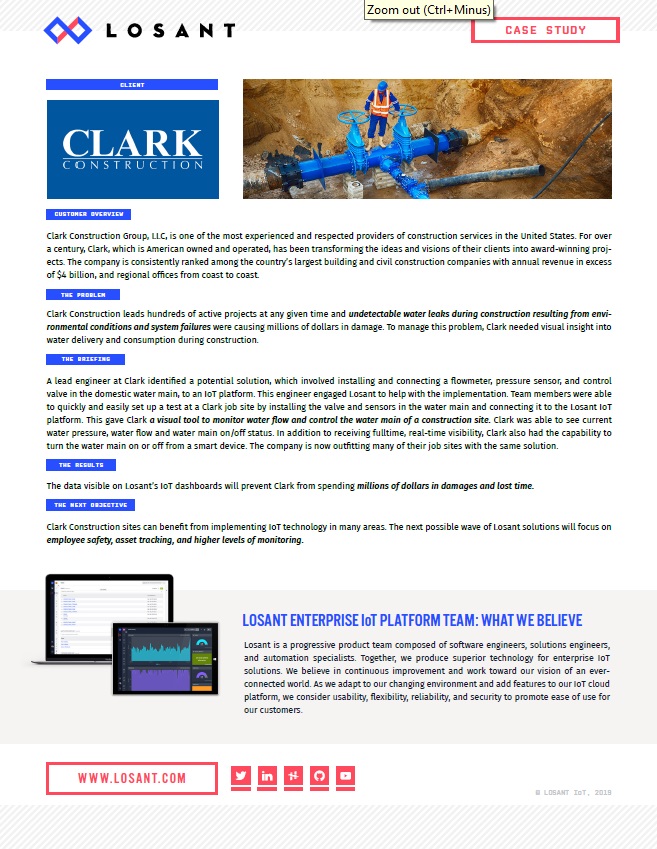

Clarke Consutrction Case Study

Clark Construction leads hundreds of active projects at any given time and undetectable water leaks during construction resulting from environmental conditions and system failures were causing millions of dollars in damage. To manage this problem, Clark needed visual insight into water delivery and consumption during construction.