Cutting through the complexities of supply chain tracking

- October 4, 2020

- Steve Rogerson

IMC executive editor Steve Rogerson discusses last week’s IMC IIoT for Supply Chain online conference.

Champions of the IoT often point to logistics and supply chain monitoring as the ideal application for the technology. Being able to track in real time the progress of goods around the world, knowing where they are and what condition they are in, is seen as a major benefit.

This is more so with sensitive cargos such as pharmaceuticals and some foods where maintaining the temperature throughout their journey can be crucial. Medicine can be destroyed and some foods can be ruined if the temperature varies by a small amount for just a short time.

Yet the challenges to achieving such a headline application are immense, and there is no one technology that can handle everything.

This was the main subject of an online discussion organised by the IoT M2M Council (IMC) last week as part of its IoT Days series. “Logistics supply chains have become more complex over time,” said Jaap Groot, CEO of Fractus Antennas, in the opening talk of the IIoT for Supply Chain conference.

One problem, of course, is the number of different ways that goods travel on their journey. Just over half go by road, about 16% by rail, 12% by pipeline and 9% by water. The other 6% fly, normally on traditional freight planes but we are now seeing drones being used for some last kilometre deliveries.

To track these goods on their journeys often involves multiple communications methods, and Groot talked about multi-rat. I had this image of small furry creatures busily noting the progress of the packages or even lots of rodents towing trailers. That was till Groot said rat actually stood for radio access technology. Ah, now that makes sense.

The radio is the most power hungry part of the whole operation, which is why Groot thinks energy harvesting will have to play a part to help battery lives achieve the five to ten year range that some boast. However, that is a long time. Think how many upgrades your mobile phone will have in that period, and so we come to another problem – upgrades. Many of these devices will need upgrading during their lifetimes.

Other difficulties include deployment. Rolling out thousands or even millions of asset trackers cannot be done overnight or even over a year or more. Security is another issue; all those devices increase the potential attack surface.

And, according to Groot, the biggest problem is coverage. There is no radio access technology that is everywhere and in some buildings and rural areas there is no coverage at all. On top of that think of the number of different protocols and bands the wireless technology may have to deal with, hence multi-rat.

Groot believes there is light at the end of the tunnel, and that is not from a fast train heading towards you. “I am enthusiastic about the future for IoT and logistics,” he said.

This complexity was picked up by Esteban Ibarra, vice president for business development at Kore, who talked about segmentation in the supply chain, saying there was no one comprehensive system to track and trace all the applications. With that comes the question of quality, ensuring the end user has good and reliable information.

Another obstacle to deploying IoT is a lack of expertise, even though the technology has been around for some time. Companies often rely on IT departments that may not be well versed with IoT.

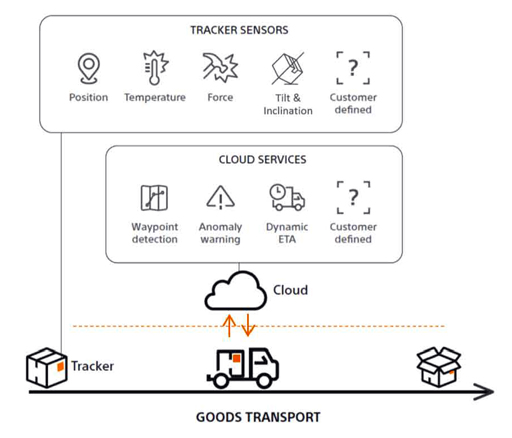

The end goal, or Holy Grail, as David Houghton, general manager for asset tracking at NimbeLink, put it, is to be able to light up all your assets and make decisions based on real-time data. He compared two types of tracking – the macro level where a particular vehicle, train or plane was being tracked with item level where the actual goods themselves are being monitored.

However, he added another layer of complexity to the task. On top of the technology was a business model, and one that could earn money rather than being an expense.

As an example, he talked about a company that rents out pallets. By attaching devices to the pallets, it can keep track of where they are and how they are being used. This can increase efficiency when it comes to deploying pallets and reduce thefts and losses.

But it is also a revenue-generating opportunity because the company now has a service it can sell to its customers by providing increased visibility of the goods as they travel.

So where does all that leave us? Logistics may be a flagship application for IoT technology, but it is far from a simple one, something touched on by all three speakers. But it is also an application that the technology can handle and the benefits in most cases far outweigh the effort. Keep on tracking!