Achieve Pallet-Level Visibility Throughout Your Supply Chain

- March 2, 2020

- imc

The disciplines of supply chain management and logistics focus an organization on driving value and creating competitive advantages by optimizing the flow and storage of goods.

From inbound logistics and order fulfillment to last mile delivery and service parts management, companies are investing billions of dollars to monitor and optimize the flow of their upstream and downstream supply chains. Despite this enormous investment, misplaced, damaged, and stolen goods continue to cost US companies billions of dollars a year in lost revenues and increased costs. In addition, consumers and retailers are increasingly demanding greater product transparency, traceability, and environmental and ethical best practices as a condition of doing business with companies. And none of this is possible without tracking the supply chain.

The NimbeLink edge-to-enterprise Supply Chain Solution brings situational awareness to the pallet level with the versatile AT6 device.

Tracking within the supply chain has primarily been ‘segment’ based. RFID, barcodes, Bluetooth beacons, and near-field communications (NFC) systems each have distinctive benefits, but present varying limitations in cost of implementation, fitment, range, infrastructure proximity, indoor and outdoor tracking ability, and the delivery of real-time data. Compounding the challenge is the lack of integration between the different technologies as goods migrate through the various routes, stages, and segments.

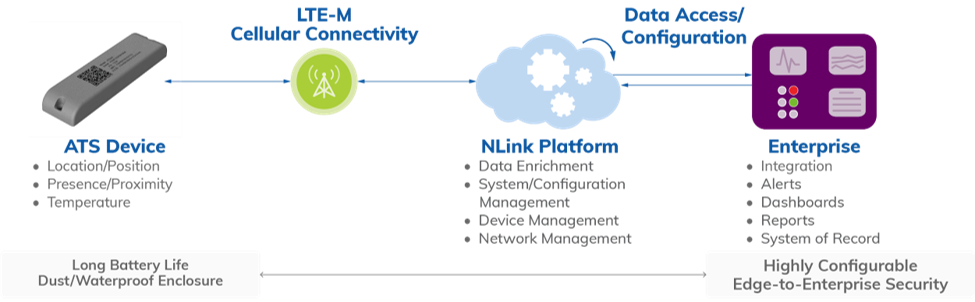

Reductions in the size and cost of asset tracking devices have recently changed the economics of autonomous tracking of non-powered assets and enabled start-to-finish tracking. By leveraging new LTE-M and NB-IoT cellular networks and edge-based intelligence, these new solutions enable point-to-point location and condition monitoring of many supply chain assets, including pallets, bins, barrels, and containers.

The new AT6 asset tracking device from NimbeLink is specifically designed for supply chain monitoring. This small, ruggedized device leverages LTE-M cellular connectivity and is configured and managed using the NLink Platform. In addition, the AT6 delivers a range of industry-leading performance benefits that create a true edge-to-enterprise solution:

? Requires no handoffs with other wireless protocols

? Works seamlessly indoors and outdoors

? Is both waterproof and dustproof

? Operates in temperatures ranging from -20°C to +60°C (-4°F to 140°F)

? Has exceptionally low power requirements and an operational life of 3-5 years

? Requires no special labels or readers, and can be deployed quickly

? Delivers secure data through established cellular technologies

? Works with pallets, barrels, bins, crates, containers or finished unpackaged products

? Provides real-time location, movement, and temperature data 24/7, even during transit

? Gracefully connects to enterprise systems

? Deters pilferage and diversion

? Provides customers with real-time delivery information

? Allows tracking and recovery of assets for re-use

? Monitors performance of logistics and delivery teams

Next-generation cellular-based supply chain solutions reduce costs and create competitive advantages by monitoring the location and condition of supply chain goods in real time, indoors and outdoors. In addition, these solutions enable higher levels of compliance with environmental and ethical best practices, and add greater transparency and traceability within the supply chain.

For more information on the NimbeLink Supply Chain Solution and the new AT6, please visit https://nimbelink.com/

About the Author

David Houghton is the Asset Tracking Solutions GM at NimbeLink, a world leader in cellular-based connectivity solutions.